WHO WE ARE

Global Energy and Environmental Solutions for Industry

Bloom Engineering improves the environmental sustainability of industrial heating applications, particularly focused on the aluminum and steel industries.

Bloom’s knowledge and experience in furnace and heating applications provides meaningful competitive advantage to our customers by reducing CO2 and NOx, conversion to sustainable fuel sources, increasing production capacity, improving temperature uniformity, reducing fuel consumption, and enhancing operating flexibility.

Headquartered in Pittsburgh, USA since 1934, Bloom serves its global customers from subsidiaries in Germany, India, and China.

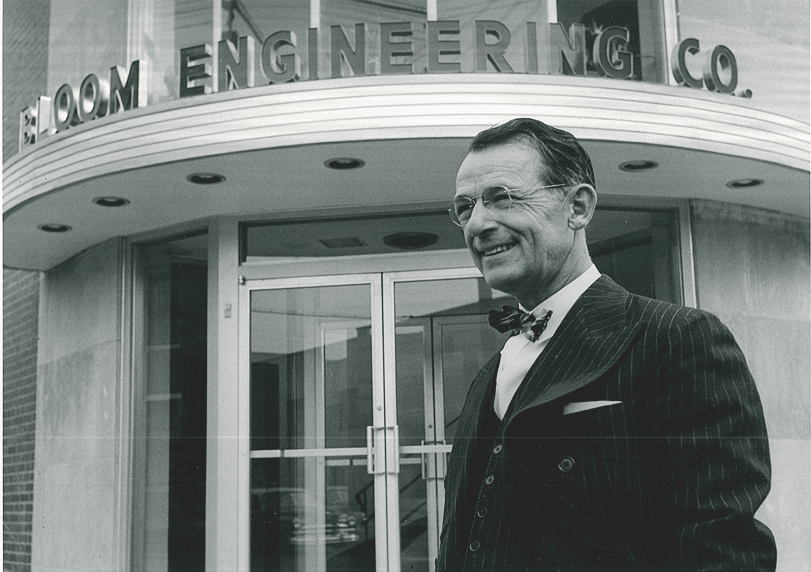

“Growth by Solving Customers’ Problems” – Fred S. Bloom

Innovation Since 1934

Founded in 1934

Bloom Engineering was founded in 1934, in Pittsburgh, PA USA, by Fred S. Bloom, with the belief that there was a dire need for improved industrial combustion products. His immediate areas of concern were safety, efficiency, and production capabilities. Early on, Mr. Bloom led the way in his focus on product technology and quantitative furnace analysis techniques.

Over 80 US and Foreign Patents

Bloom Engineering has been awarded more than 80 US and foreign patents for advances in combustion and furnace technology and continues to hold innovation as a core value that delivers long term benefit to our customers.

Bloom Engineering Becomes a Wabtec Company

In December 2024, Bloom Engineering joined Wabtec as part of its Freight and Industrial Components Group, strengthening Wabtec’s portfolio of heat transfer and energy solutions. Bloom Engineering’s advanced technologies in burners, combustion systems, and overall services for industrial and process heating applications complement and extend Wabtec’s existing capabilities.

Development of unique baffle burner concept

Many years ago, Bloom Engineering developed the unique baffle burner concept which is still applied to its range of direct fired burners. The modern recuperative radiant tube burner has its origins from the early 1950’s. Complementary products also include controls, valves, prefabricated pipe racks, ladle and tundish heating and drying stations and related combustion equipment. With our extensive research and development complex, combined with modern manufacturing facilities Bloom Engineering can support our customers’ needs, and help them find a solution.

Repair, maintenance, upgrade, and remanufacture services

Repair, maintenance, burner upgrade and equipment remanufacture services ensures original quality and lower overall costs while increasing craft labor availability at the customer's plant.

The necessity of reducing NOx emissions.

The world recognizes the necessity of reducing NOx emissions. Although most of Bloom Engineering’s original burners were inherently designed for low NOx, modifications have reduced emissions even further to meet the challenges presented by clean air requirements, making us a global leader in this technology. With the development of regenerative burners, our low NOx baffle innovations successfully solved the challenges presented by regeneration's high temperature combustion air characteristics. To meet radiant tube burner users' improved air quality requirements, Bloom implemented creative design changes.

Burner innovations

Bloom Engineering have always demanded that burner innovations reach the market with uncompromised thermal performance and the ability to use a wide range of fuels, which, in addition to natural gas includes oil, liquid biofuels, process off-gasses, manufactured gasses, and hydrogen. We strengthen our historical reputation for low carbon monoxide emission leadership and rugged construction with each new offering. Other refractory products include preformed ports to reduce furnace rebuilding time.

Knowledge of the various heating applications of equipment

Bloom Engineering prides itself on having in-depth knowledge of the various heating applications in which its equipment is used. The customizable product line, extensive installation list, R&D capability, and on-site field service experience, allows Bloom Engineering the ability to provide the best possible solution for each unique situation.

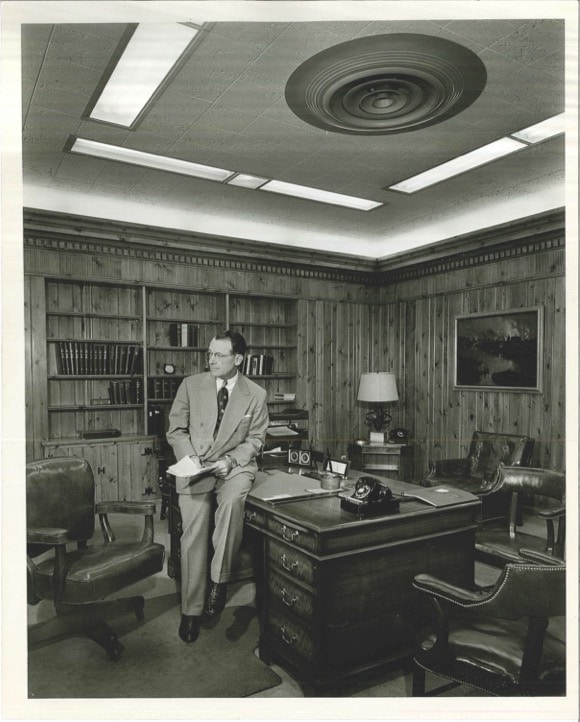

Develop proper engineering solutions to solve our customer's problems

Above all else, we are an engineering company, and our focus is to develop proper engineering solutions to solve our customer’s problems. We custom engineer our products, to help achieve optimal results from heating equipment that might not have been possible using a standard “catalog” type product.

“First, understand the customer’s problem. Then define it in terms that allow a calculated, engineering solution. Apply properly designed equipment in the correct arrangement so that the furnace will produce the desired results in terms of capacity and quality. Last, but not least, go back to the installation and make sure that the furnace is living up to what the calculations indicated it should.”

-Fred S. Bloom